| Bfn Production and placing ecoblock revetments | |

|---|---|

| Context | Bfn Building for Nature project |

| Decompositie type | IOR |

For the production of the concrete blocks two different techniques were applied. Handmade concrete blocks were produced at the HZ facilities and factory produced blocks were produced at Haringman Betonwaren, according to the standards used for productions of revetment blocks for dykes. This also led to two different ways of placing the blocks.

Handmade concrete blocks

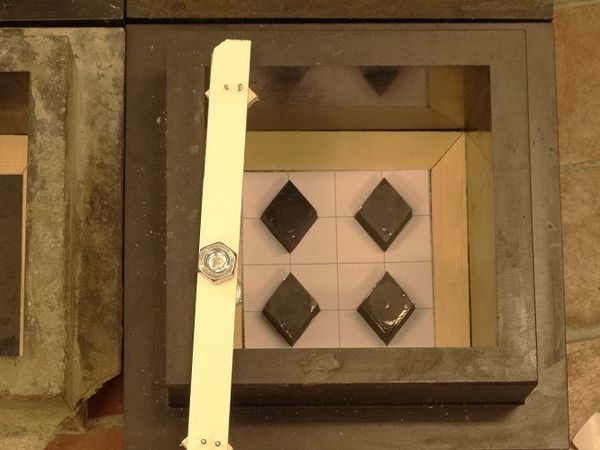

The handmade concrete blocks made use of the HZ facilities including the concrete laboratory and 3D printers, for an accurate production of the shapes. The shapes were later used on the molds to serve as templates to create the cavities in the concrete blocks (Figure 1.). The concrete used in the production was class C28/35 with 12 mm bulk aggregate and the molds for the concrete blocks were the molds traditionally used to test Compressive Strength of Cubic Concrete Specimens. On the bottom of the mold the chamfer strips and the 3D printed shapes were applied according to the technical specifications. After placing all the elements in the mold, the release oil for concrete was applied. The concrete was poured and before being tempered a bolt was applied. After a total period of five days curing in the wet chamber the blocks were considered ready to be applied and were stored ready to be shipped to the test location which happened a month after.

The handmade blocks were applied on a steel structure at NIOZ and also at Krabbenkreekdam (for comparison with the blocks at NIOZ, Yerseke. (Figure 2.)). The blocks were transported to the locations by vans and trucks and were placed at low tide. At the test location, the blocks are arranged on three different heights, with the long axis of the pyramidal shape facing the water to maintain consistency. The blocks were attached to steel structures with the bolt present in the back of the block and then systematically photographed to show the change in biological growth over time. The results of this first test were used as input for the factory produced blocks.

Factory produced hydroblocks

The factory produced concrete blocks were produced at Haringman betonwaren B.V. in Goes. Around 3.500 blocks were produced using a “dry mixture” of concrete which comply with several certifications (KOMO and BENOR) (Figure 3.). The concrete is similar to the concrete mixture of other concrete blocks but could be adjusted to compensate for the weight loss due to the cavities. The stamps from the desired designs were produced in steel. The blocks were in total 30 + 5cm in height and the shapes were stamped on these extra 5 cm layer. The blocks were cured for 28 days and afterwards stored while waiting for shipment to the test location.

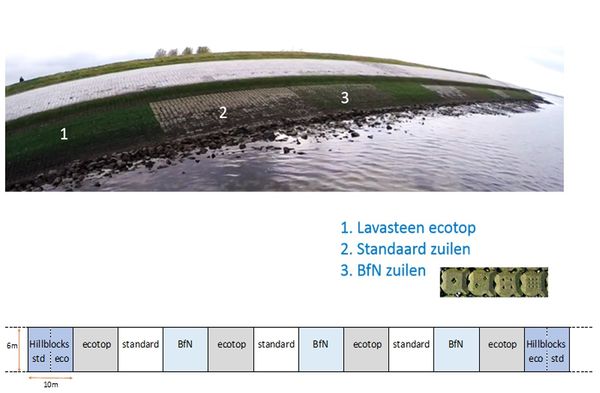

The factory produced blocks were implemented as a traditional revetement of a dyke. Nevertheless, first, permission for the experiment at Sint Annaland was given by the waterboard and Rijkswaterstaat. The factory produced blocks were implemented at the dyke reinforcement project in the area and the new revetment was used to replace the existing one (Figure 4.).

Besides the factory produced blocks, other blocks were also placed at this location with the intention of comparing the new designs with existing ones (Figure 5.). The work was performed by the contractor KWS. And along the dyke the only element that changed was the block type. Other elements of the dyke reinforcement, e.g. filter layer, remained constant.

De View-Navigation (VN) pagina's.

De links naar andere pagina's.

| Produceert | |

|---|---|

| Consumeeert | Bfn Design ecoblock revetments |

| Onderdeel van | Bfn Designing and researching ecoblock revetments |

| Instantie van | |

| Betreft |

Connectie.

| Connectie type | seq |

|---|---|

| Connecteert naar | Bfn Data collection ecoblock revetments |

| Conditie | |

| Opmerkingen |

De pagina's die linken naar deze pagina.

Dit element heeft geen subelementen.

| Komt van | Type | Connectie type | Conditie | Waarde | Opmerkingen |

|---|---|---|---|---|---|

| Bfn Design ecoblock revetments with stakeholders | Connects | seq |